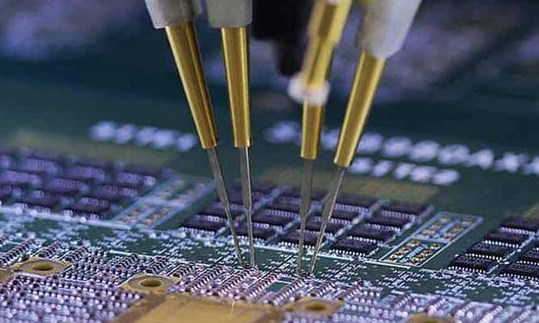

IC testing refers to the process of testing integrated circuits (ICs) to ensure their functionality, performance, and reliability. It is a crucial step in the semiconductor manufacturing process to identify and eliminate defective components. In this passage, we are going to explain the 8 types of integrated circuit testing and the reasons that cause integrate circuit to break down.

What are the 8 Types of Integrated Circuit Testing

Integrated circuit testing is an essential process to ensure the quality, functionality, and reliability of semiconductor devices. There are various types of testing techniques applied at different stages of the production process to validate the performance of integrated circuits. Here are eight common types of integrated circuit testing:

-

Wafer Testing: Wafer testing, also known as wafer probing, involves testing the electrical characteristics of individual dies on a semiconductor wafer before they are diced and packaged. This process helps identify defective dies and ensures that only functional dies are used for packaging.

-

Bare Die Testing: Bare die testing involves testing individual unpackaged dies after they have been separated from the wafer. This testing process helps detect any defects introduced during dicing, handling, or cleaning processes.

-

Package Testing: Package testing involves testing integrated circuits after they have been encapsulated in a package. This type of testing validates the functionality of the packaged device and ensures that it meets the specified performance requirements.

-

Temperature Testing: Temperature testing involves subjecting integrated circuits to different temperature conditions to assess their performance across a range of operating temperatures. This type of testing helps ensure that the circuits can operate reliably under varying environmental conditions.

-

Burn-In Testing: Burn-in testing, also known as stress testing, involves running integrated circuits at elevated temperatures and voltages for an extended period to identify early failures and ensure long-term reliability. This testing helps detect potential defects that may manifest under normal operating conditions.

-

Functional Testing: Functional testing involves verifying that the integrated circuit performs its intended functions correctly. This type of testing assesses the circuit's logic, timing, inputs, and outputs to ensure that it meets the required specifications and functionality.

-

RF Testing: Radio-frequency (RF) testing involves assessing the performance of integrated circuits that operate at high frequencies. This testing includes measuring parameters such as gain, noise figure, and output power to validate the RF performance of the circuits.

-

Electrical Characterization: Electrical characterization testing involves measuring various electrical parameters of the integrated circuit, such as voltage, current, resistance, capacitance, and inductance. This type of testing helps assess the electrical properties and performance of the circuits.

These are some of the key types of integrated circuit testing techniques used to ensure the quality, reliability, and functionality of semiconductor devices throughout the manufacturing process. Each testing method plays a crucial role in identifying defects, validating performance, and maintaining the overall quality of integrated circuits.

What Causes Integrated Circuit to Break Down

Integrated circuits, commonly known as ICs or microchips, are highly sophisticated electronic components that can be susceptible to various factors that can cause them to break down or fail. Here are some common reasons why integrated circuits may break down:

-

Voltage Spikes/Surges: Excessive voltage spikes or power surges can cause integrated circuits to fail. If the voltage exceeds the maximum ratings specified for the IC, it can lead to overheating, electrical breakdown, and damage to the internal components.

-

Overheating: Integrated circuits generate heat during operation, and excessive heat can degrade the performance and reliability of the IC. Overheating can be caused by inadequate cooling, improper heat dissipation, or operating the IC beyond its specified temperature range.

-

Electrostatic Discharge (ESD): ESD occurs when a sudden flow of static electricity passes through the IC, causing damage to its sensitive electronic components. Handling ICs without proper ESD protection or working in environments with high ESD risk can lead to failures.

.jpg)

-

Incorrect Handling: Mishandling of integrated circuits during installation, testing, or repairs can cause physical damage to the components, such as bending pins, cracking the package, or exposing the IC to contaminants, resulting in potential failures.

-

Manufacturing Defects: Errors or defects introduced during the manufacturing process can lead to IC failures. Defects such as contamination, incomplete connections, or improper doping can affect the functionality and reliability of the IC.

-

Ageing and Wear: Over time, integrated circuits can degrade due to factors such as material fatigue, electromigration (the movement of atoms within the IC), or silicon crystal defects, leading to a gradual loss of performance and eventual failure.

-

Excessive Current: Passing excessive current through an IC can cause electrical overstress, leading to damage to the internal circuitry, metal interconnects, or junctions within the IC.

-

Environmental Factors: Exposure to harsh environmental conditions, such as high humidity, temperature extremes, corrosive chemicals, or radiation, can accelerate the degradation of materials within the IC and cause premature failures.

-

Mechanical Stress: Mechanical stress from factors like thermal expansion, vibration, or physical shock can cause microcracks, solder joint failures, or other mechanical damage that compromises the integrity of the IC.

-

Design Flaws: Inadequate IC design, including signal integrity issues, insufficient margins, inadequate power distribution, or improper decoupling, can lead to unexpected malfunctions or failures.

By understanding these potential causes of breakdown in integrated circuits, designers, manufacturers, and users can take appropriate precautions to mitigate risks, enhance reliability, and ensure the longevity of electronic components in various applications.